|

Why Select a Trulock Choke Tube?  George and Scott Trulock It is the 40th anniversary of Trulock chokes, but in this case, it is bittersweet. I lost a trusted and greatly valued long-time friend earlier this year, with the passing of George Trulock . . . and so did the entire shooting sports industry. George was innovative, hard-working, resolutely honest, and rightly quite proud of his family, his company, and his community. You can read more about George right here https://www.clarkfuneral.com/george-c-trulock-jr-br-july-28-1954-june-13-2022/ which should give you a sense of what made him so very special. Trulock President, Scott Trulock, and company proficiently carries on the Trulock legacy of quality, service, and performance. George would be rightfully proud.

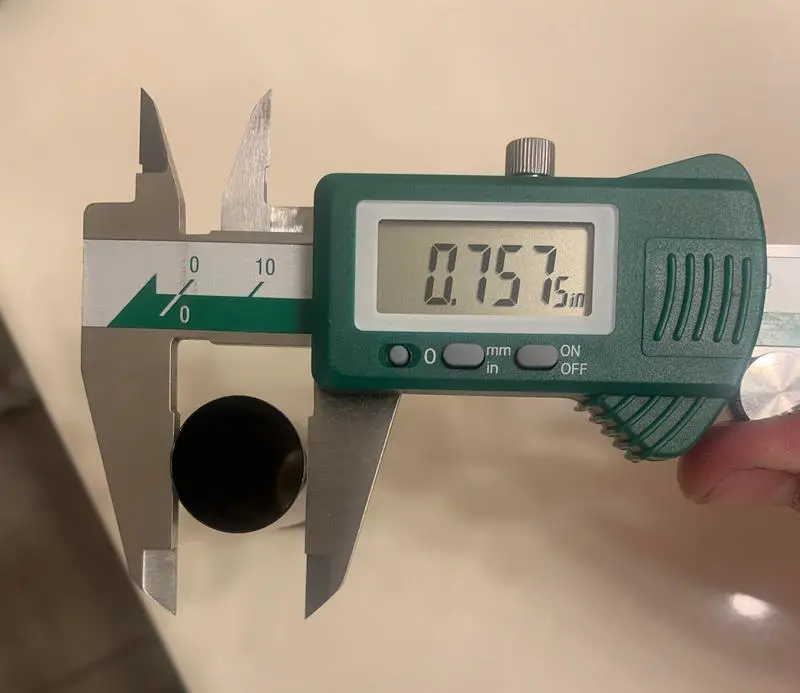

Above: an example of an egg-shaped factory choke tube, off by over .021 inch, at least. Choke tubes can be a confusing mess, helped along by senseless ad-brags and empty-headed claims from shotgun manufacturers. Many well-known shotgun manufacturers supply mismarked choke tubes, egg-shaped choke tubes, and poor quality tubes that have little chance of producing patterns that are anywhere near what the markings promise. As George has long demonstrated, if you want a good pattern it takes both a high quality shell and a high quality choke tube. No choke tube can take gravel and transform it into perfect spheres. The purpose of a choke tube is to simply control pattern diameter. The ideal choke for you is the one that gives you the largest effective diameter with your shells, at the ranges you plan on shooting at. Trulock chokes perform as marked or better. You'll be satisfied, or your money back. George pioneered this satisfaction guarantee along with the Trulock lifetime warranty. Particularly with steel and other hard shot materials, factory chokes are often out of gas with what they call “Modified” chokes. Trulock chokes are made from 17-4 stainless, heat-treated to 200,000 PSI. As a result, you have the option of using Improved Modified chokes with steel, tungsten, and essentially all shot materials with standard Trulock chokes. As soon as I started using Trulock chokes many years ago, my choke issues disappeared. Here's just one example, from nine years ago, using a Trulock Improved Modified choke vs. the then-new Browning Invector-DS Improved Modified choke. The difference is astounding. https://youtu.be/ip9THBdIu3s . Sometimes, factory chokes are horrifically eccentric, as is the case with some Beretta chokes as shown above. It is hard to believe that choke tubes like this are shipped to the hapless consumer with a new shotgun, but it happens. The majority of shotguns that I review have mismarked, underperforming choke tubes. Some are so bad that some of the supplied chokes, regardless of how they are marked, throw close to the same pattern perecentages. It is frustrating to spend the afternoon at the patterning board, only to discover that there is no supplied choke that is suitable to hunt with. The more factory chokes that quickly hit the garbage can, the happier I generally am, for I'm saving the time, effort, and the ammo wasted fighting crummy factory choke tubes.  Trulock chokes are designed and developed by the only method that actually works: constantly putting shots on paper and carefully tabulating the results with a wide variety of traditional and newer shotshells and shot materials. There is no guesswork involved, just work. That's how Trulock can tell you not only what chokes works best with a Winchester Long Beard XR load, for example, but what works best with Long Beard #6 shot, Long Beard #5 shot, and Long Beard #4 shot as well. That's a level of testing most shotgun manufacturers can't seem to be bothered with. As the majority of autoloaders and O/U's sold in the United States are made in Japan, Italy, Turkey, Portugal, and so forth, some of this is quite understandable, for these guns are not specifically designed for, much less actually tested with the latest American ammunition.  Trulock Precision Hunter choke tubes have stocked my freezer more than anything else. The Trulock method of fine dining is a reliable and delicious one, one that has saved me immeasurable frustration over the years. It will do the same for you as well, or your money back. Raised in Whigham, Georgia, George Trulock, Jr. was a true patriot, proud Southerner, and a pillar of the community he loved. George worked tirelessly his entire adult life to make Whigham the very best it could be. At the age of 22, he was elected to the Whigham City Council and at the time was the youngest member to ever serve as a councilman. He served on the council for a total of 30 years as well as holding the office of Whigham Mayor for over 14 years, which he held at the time of his death. George served as a police officer for the Cairo Police Department from 1972 until 1982. An avid firearms enthusiast and businessman, Mr. Trulock was a talented gunsmith; and during his time as police officer, he began building his business on a part time basis. In 1982, he went into the firearms business full time and founded Trulock Firearms, which later became Trulock Tool Company. George grew his company from a one-man-show to a business that currently employs 30 people. George was the developer of the Tru-Choke design, which has been replicated by many firearm companies throughout the years. Trulock Tool Company is now known for producing quality, custom-designed choke tubes and gun parts, shipping chokes worldwide. Trulock Chokes will remain a family-owned and operated business. Trulock believed it was his duty to help promote and protect the industry he so loved. He was an NRA Endowment member, former local NRA chapter president, a member of the National Shooting Sports Foundation and the Heritage Foundation. |