|

Guns and Shooting Online Project Gun: By the Guns and Shooting Online Staff  When we reviewed the Ruger New Bearcat Stainless .22 revolver recently, we liked it a lot. However, as we usually do in the course of a gun review, we made some suggestions about improvements that we thought Ruger should make to their little single action kit gun. (You will find our review "50 Years of the Ruger Bearcat: The 2008 New Bearcat Stainless Revolver" on the Member Side Product Review page. Since Managing Editor Chuck Hawks purchased the test Bearcat for his own use and we haven't done a G&S Online project gun in a while, we decided to go ahead and make the suggested improvements ourselves. Guns and Shooting Online's Gunsmithing Editor, Rocky Hays, agreed to do the work, so we were in business. We would name the result the "G&S Online Super Bearcat Stainless." The primary suggestions for improvement that we made in our review included:

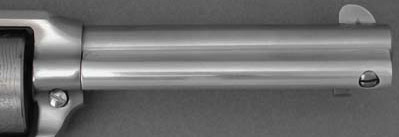

We had expected that we would also have to polish and adjust the stock trigger to produce approximately a three-pound trigger pull, but in the case of our test gun, this proved to be unnecessary. Our test gun's trigger released at a clean 2-7/8 pounds right out of the box, the best trigger that we have ever encountered on a Ruger revolver. The trigger on your Bearcat revolver may vary, but if it does, Rocky can fix it. We decided to make the first four changes on the list above and hold off on the fifth (adjustable sights). Chuck had a hunch that if we re-chambered the gun to .22 WMR it might shoot a lot closer to the point of aim of the stock fixed sights, so we decided to find out before altering the frame to accept an adjustable rear sight. Due to the small size of the Bearcat frame, a petite adjustable rear sight should be made specifically for the Bearcat and this would require a factory modification. An adjustable rear sight would likely also require a miniature ramp front sight along the lines of the Blackhawk's, which would be an improvement in itself. We urge Ruger to do just that.  The easiest improvement on our list is lightening the hammer spring (or "mainspring," part KPR00402 in the exploded diagram above) and Chuck decided to do it before turning the revolver over to Rocky for further professional treatment. Please note, before we go any further, that Sturm, Ruger absolutely DOES NOT recommend modifying their firearms in any way. If, after reading this article, you decide to attempt any of these modifications the result is entirely your responsibility and neither Guns and Shooting Online nor Sturm, Ruger assume any responsibility for your actions. If you are not a competent gunsmith, consult someone who is before attempting to modify your Bearcat! Perhaps the best way to lighten a Ruger SA mainspring is to replace the stock spring with a reduced power hammer spring. This is what a custom gunsmith like Rocky Hays does. Being a cheapskate and having done it several times before, Chuck decided instead to lighten the force of the stock spring in his revolver by reducing its length. To accomplish this, the grips must be removed. Next, cock the revolver and slip a small finishing nail through the hole in the hammer strut (PR-15); pull the trigger to release the hammer, ease it fully forward with your thumb and you can now remove the hammer strut and the concentric mainspring. You can use a small vise and a pair of vise grips to compress the mainspring and remove the nail, freeing the mainspring. Be careful not to let it get away from you, it is a powerful spring. Use the same tools to reassemble. Use a set of diagonal pliers to cut three links from the end of the spring. File the cut edge flat. Reassemble. The result is a lighter, more comfortable hammer draw and the hammer blow is still more than sufficient for reliable ignition. Polishing the aluminum ejector rod housing (PR-22) to better match the gun's finish improves the revolver's appearance. This is the only part that we could see on the whole gun that isn't made of stainless steel. Ruger should supply the Stainless Bearcat with a stainless steel housing, but they don't. The housing's gray finish, which appears to be some sort of paint, must be removed before the aluminum beneath can be polished to a satin sheen that approximately matches the rest of the gun. Rocky has the power tools and expertise required to do a professional job and he did just that.  The Bearcat hammer is manufactured with very sharp edges and this makes it actively uncomfortable under the thumb. (Chuck actually managed to cut his finger on the edge of the stock hammer--don't ask how!) Rocky "melted" (rounded off) the edges of the hammer. The result is a far more comfortable hammer. The slightly rounded edges of the hammer coupled with the reduced main spring tension make the Bearcat a lot more user friendly. Rechambering the revolver to accept .22 WMR cartridges is the most time consuming of our modifications. (Revolvers, after all, have six chambers.) Rocky does this entirely by hand (no power tools involved) to insure a perfect result, finishing the new chambers with a very fine finishing reamer. The result is perfect, SAAMI spec chambers with properly recessed case rims, just as Ruger intended.  In order to provide sufficient clearance for the very slightly thicker .22 WMR cartridge rims (compared to .22 LR rims), Rocky found it necessary to polish the recoil shield inside of the Bearcat's frame. This attention to detail allows the revolver's cylinder to turn freely, but retains minimum clearance for proper headspacing. The finishing touch on the G&S Online Super Bearcat Stainless .22 Magnum is the engraving. We could not help but notice that the shape of the Bearcat's Remington-pattern frame leaves a lot of space between the rosewood grip panels and the cylinder opening. Just right, we figured, for a Guns and Shooting Online logo, the same one that appears on the front of our Guns and Shooting Online T-shirts. Rocky is an active member of the Engraver's Guild and is well known for his lavish engraving and precious metal inlays, so he is well qualified to hand engrave a Guns and Shooting Online logo on the left side of the Bearcat's frame. He went a step farther and surprised Chuck by filling the central "GS" in the logo with a gold inlay. This is classy work of the sort that might be found on the bottom plate of a "best grade" shotgun and when he saw the result, Chuck was stunned.  With the completed G&S Online Super Bearcat Stainless .22 Magnum revolver in hand, the Guns and Shooting Online staff was understandably anxious to get the little revolver to the range to see how it performed. Chuck Hawks, Rocky Hays and Bob Fleck did the shooting for record. This was done at the Izaak Walton outdoor range south of Eugene, Oregon. The autumn weather was cool and overcast, but not raining and wind was not a factor. Our 25 yard test firing for record was done from a shooting bench using a Shooter's Ridge Steady Point Handgun Rest. (There is a review of this pistol rest on the Handgun Information Page. -Ed.) We used Hoppe's Competition 25 yard Slow-fire Pistol Targets. We had several types of .22 WMR ammunition on hand for testing. These included Winchester Super-X 40 grain JHP, CCI Maxi-Mag 40 grain JHP, Federal Classic 40 grain JHP and CCI Maxi-Mag 30 grain Poly-Tip V-MAX loads. Here are our shooting results.

In our initial review of this same Ruger Bearcat Stainless revolver in .22 Long Rifle caliber, it had produced satisfactory, but not exceptional, accuracy. After rechambering to .22 WMR, there was little change in the accuracy potential of our test gun, as you can see by comparing the results from our initial review (see the Product Review Page) with the results above. A lightweight, 4" barrel can only do so much, but the G&S Online Super Bearcat should make an excellent kit gun for the field and a fun plinker. This little revolver also has survival and self-defense applications, since a 50 round box of .22 WMR cartridges occupies little more space than a box of .22 LR cartridges, but the Magnum caliber shoots much flatter and hits much harder, greatly extending the useful range. We took the opportunity to chronograph the Winchester Super-X 40 grain JHP load from the Super Bearcat's 4" barrel. The result was a average instrumental velocity of 1231 fps measured 10" from the muzzle. (Winchester claims a MV of 1480 fps from a 6.5" test barrel.) The extreme spread was 44 fps, indicating good uniformity for .22 WMR rimfire ammunition. This is impressive performance from so petite a revolver. What changed is the point of impact, and for the better. As we reported in our review of the stock .22 LR pistol, the fixed sights caused all shooter's groups to average approximately an inch low and about 3" to the right of the point of aim at 25 yards (some shooters were printing about 4" to the right). This is unfortunate, but typical of our experience with fixed sight guns. We mentioned earlier in this article that Chuck had a hunch the sights would prove to be better regulated for .22 Magnum ammo than for the original .22 LR chambering, and he was right. Our groups after rechambering to .22 WMR centered between approximately dead-on and about 1.5" high in elevation, depending on the individual shooter. In windage, the .22 Magnum groups hit at the point of aim to about 1.5" right, again depending on the individual shooter. This is, altogether, a much better performance! Chuck is now sure that he will not need to have adjustable sights installed on this revolver. A minor amount of filing on the rear sight notch will cope with any remaining discrepancy. Your results, of course, may vary. |