|

The Shotshell and its Development Old habits die hard. We still talk about brass when it isn't, refer to drams when they are not used, talk about blown and cartwheel patterns, and we delight in musing about pressure although it is often not relevant. Many of these things were, at one time, but are mythological relics today. For a good long while, as noted by Gerald Burrard, felt wads were the standard, with white felts being by far the best quality. The cheaper felts made shotshells “almost useless if any sort of pattern quality is desired.” Lead melts at 651.5 degrees F., and 5000 degree hot gas blowing past a wad disrupts and destroys the shot column, can weld lead pellets together, resulting in miserably erratic but sometimes amusing junk level patterns. So-called low pressure loads were in vogue, as felt could not withstand an 11,000 PSI load on a hot day. Pellets were free to jostle and bang themselves against barrel walls, the result being abraded and flattened pellets. The normal distribution (Gaussian symmetrical bell curve) found in modern patterns was a rarity as a result. Winchester Ballistician Ed Lowry wrote, “After the pellets in a shot charge clear the muzzle, and are in free flight, each of their individual flight paths experiences a number of deflections which vary randomly in both direction and magnitude. The deflections of any one pellet, moreover, are unaffected by those of any so that the pellets all move independently. Yet, collectively, their points of impact produce a definable frequency distribution on the signature sheet.” “The dispersion of pellet holes on a signature sheet conforms to the so-called "normal" or "Gaussian distribution", more familiarly known as the "bell shaped curve". This was reported by Journee in his 1902 "Tir de Fusils de Chasse", subsequently corroborated with hundreds of patterns at the Western Cartridge Co. (now the Winchester Division of Olin Corp.) in 1946 and also publicly reported by Oberfell and Thompson in 1957. A further number of extensive experimental programs at the Winchester research range established the effects of range, choke constriction, shot size and atmospheric conditions on pattern values.”

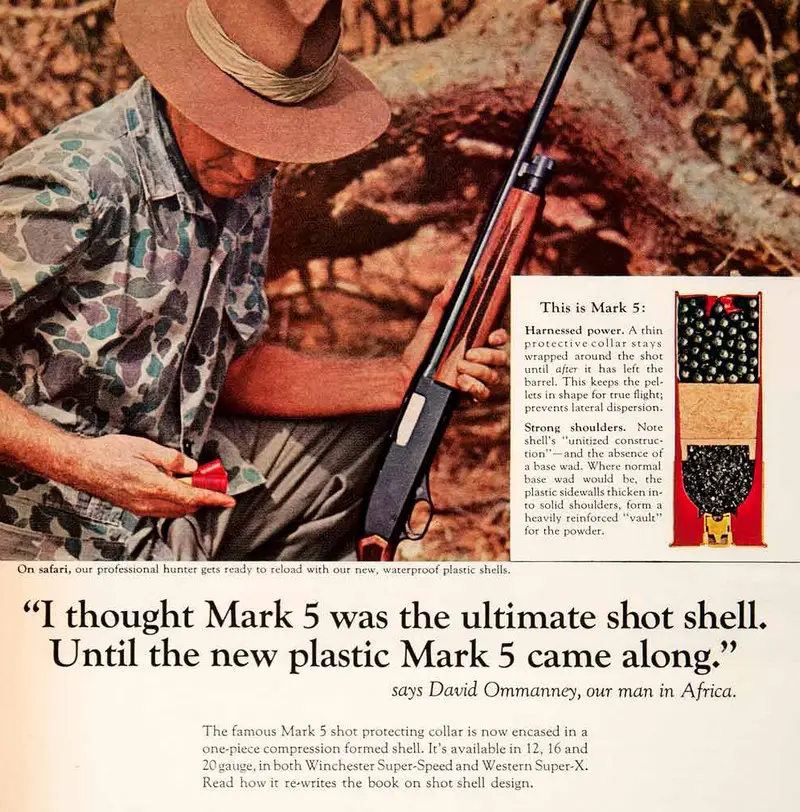

The significant breakthrough from Winchester was the Mark V collar. By protecting lead shot, the Mark V collar exceeded all expectations at the Patuxent and Nilo Farm studies. It was 1962 when the Winchester Mark 5 shot collar was introduced, finally enclosing the shot column and greatly improving patterning performance. Lowry was able to show that the pattern percentage loss due to the myth of shot string effect under the worst conditions, 55 mph ducks moving across the line of fire at 65 yards, was only 3.4 to 4.1 percent. Trivial compared to shotshells themselves, that can easily vary in pattern percentage 10% or more from shot to shot. The greatest loss was with steel, not with lead, and buffered lead loads proved substantially superior to regular lead loads as well. Lowry also discovered that shot string was not just a matter of choke, but had little to do with gauge. It was a matter of how cleanly the shot was released from the wad, more than the gauge. The two most important factors in pattern performance remain the choke itself and the quality of the shotshell. If

there is good news, it is that gauge, bore diameter, forcing cones,

and so forth don't matter from a practical perspective. Nor does

chamber length, even though a 2-3/4 in. unfolded length shell tends

to pattern more efficiently in a 2-3/4 in. chamber than a 3 inch or

3-1/2 inch chamber, it isn't enough to matter. Only the specific

shell and the specific choke control pattern quality significantly.

If there is "bad" news, it is just that the selection of

choke and shotshell for a specific application remains a trial and

error process we have to conduct for ourselves at the pattern board.

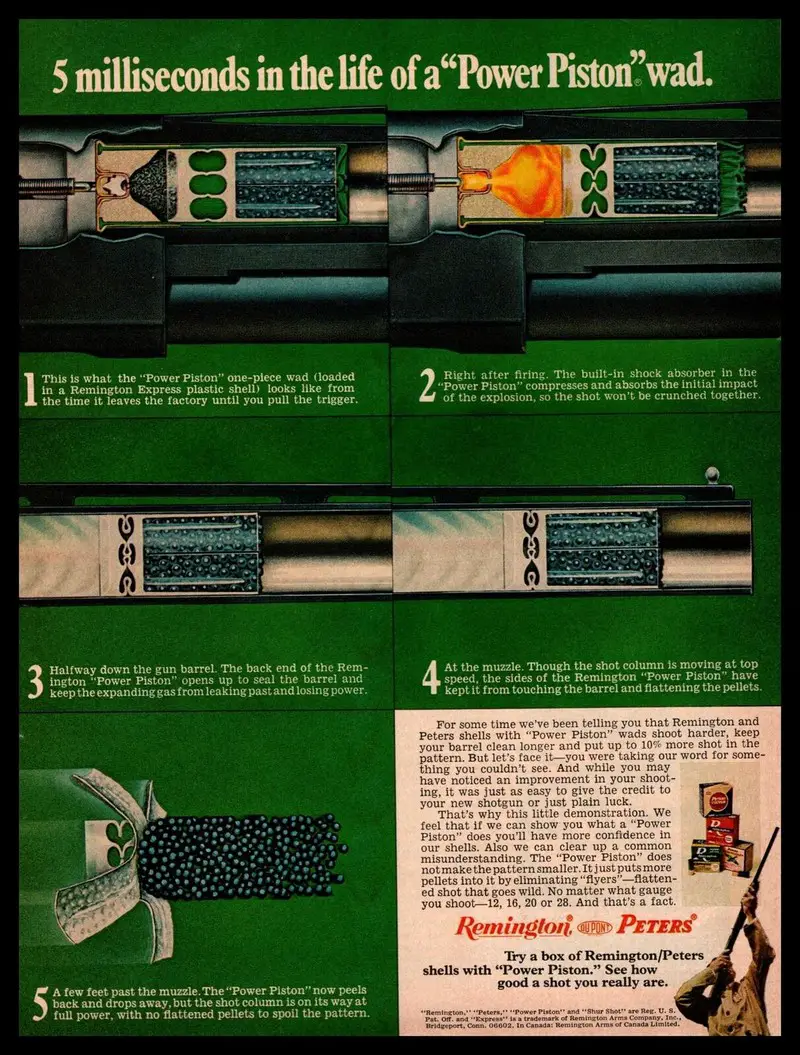

In 1964, Remington introduced their Power Piston wad: the greatest single advance in shotshell performance to date. Gone for good are blown and cartwheel patterns, failed felt, cork, and paper wads, and assorted erratic pattern issues. Unlike the highly intoxicated marketing manure of back-boring and forcing cone hucksterism, the Remington Power Piston spectacularly delivered on its 10% more shot in the pattern claim, and more when coupled with STS / Nitro 27 level 6% antimony shot. Lead shot patterns were far more predictable, efficient, and consistent than ever before and that remains the case today. The most efficient shotshells from the 2016 testing by Neil Winston were Remington 6% antimony 1-1/8 oz. #7-1/2 STS loads that did 77.9% @ 40 yards, 10 shot average, Full choke. These were the most efficient shotshells tested from several brands. The shotgun community wastes a staggering amount of money on so-called “back-boring,” forcing cones, and other various and sundry items that do nothing that has ever been shown for pattern performance, yet ignores what clearly does give results: a quality shell in concert with a quality choke. It applies to steel loads as well. Joe Hunter tested several steel loads at 40 yards. Most factory "Modified" chokes are considered "Full" chokes when using steel shotshells. To suggest that all #2 steel shotshells do not perform identically is a severe understatement. Following are his

patterning results from a 12-gauge 3" Remington 870 Special

Purpose with a 28" barrel and factory flush Rem-chokes (pattern

average of five, 30" post-shot scribed circle, yardage taped

muzzle to target, in-shell pellet count average of five, and true

choke constriction from bore gauge). Despite using the identical gun, choke, supposed #2 shot size, and 40 yard range, pattern efficiencies varied between 58% and 77%, with Remington Nitro Steel coming out on top: far exceeding any imaginary benefits from forcing cone, over-bore, and cryogenic treatment. If you'd like higher efficiencies yet from this Remington (or other brand of shotgun), just screw in a Trulock Precision Hunter Improved Modified choke. The Trulock PH Improved Modified PHREM12705 is steel-rated, yet gives you a .025 inch nominal constriction, a significant increase from most factory chokes. See https://trulockchokes.com/ for more info. |