|

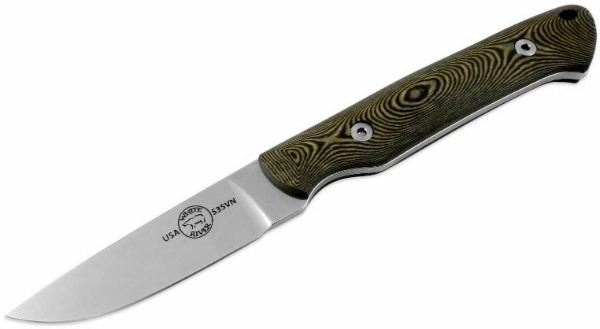

White River Knife & Tool Handle Material: From WWII to Knife Handles Courtesy of White River Knife & Tool, Fremont, MI, USA One of several handle materials White River (www.whiteriverknives.com) uses on their knives is Richlite. Actually, White River uses several handle materials, ranging from various types of Micarta, G10 phenolic, stabilized exotic woods, antler, various colors of 550 para cord and more. The choice of material depends on the design use of the knife in most cases. White River's Richlite handle material has an interesting military background, hence this short story.  Green camo Richlite handle from White River's Bakr Bilt Series. Richlite is very thin sheets of paper and when combined with epoxy resin, stacked (laminated) and put under great pressure and heated to cure becomes an incredibly tough, dense, durable material that machines like wood. Richlite has been used for decades in the food industry for counter tops and many other purposes. Richlite proper began its manufacturing life in Washington state in 1943, but prior to that the technology has a WWII military history; now, for the rest of the story. In 1943, during WW II, American B-17 and B-24 heavy bombers were getting shot to pieces in daylight raids by German fighters. The bomber's operational range far exceeded the Allied fighter escort range and when over much of the enemy territory the big bombers were on their own and provided easy targets for fast flying German fighters. The solution was to increase fighter escort range by strapping on extra drop-type fuel tanks. When the time to fight came, the fighters would jettison the external tanks and defend the bombers from German interceptors. The problem was aluminum tank material was in short supply and there was production volume to consider with the potential of fighters dropping tens of thousands of fuel tanks. Time to solve this problem was dangerously short, as the strategic bombing effort was suffering high losses. It was the British who came up with a unique solution: manufacture fuel tanks out of Kraft paper impregnated with resorcinol glue. The more complicated nose and tail cones were cut and laid-up by hand. With interior wood baffles holding the tank's composite cylindrical shape, the Brits were basically making papier-mache fuel tanks! Once completed, the tanks received two coats of cellulose dope, two coats of aluminum paint and were pressure tested. They then had a functional drop tank. The one time use tanks were tough. They had to be when operating at 20,000+ feet filled with 100-110 gallons (about 700 pounds) of volatile high-octane aviation gas at 45 degree below zero temperatures and moving along with the bombers at 200-250 miles per hour. When empty they weighed little and this made for easy handling by ground support crews. The many thousands of dropped "paper" tanks proved useless to German war effort metal scroungers. In 1943, this particular laminating technology was brought to the United States and the rest is history. American made Richlite handles on all American made White River Knives are seriously tough, proven thousands of times in combat in the skies above Europe! |