|

Buck Model 183 Blackout Crosslock Folding Knife By Gary Zinn  Image courtesy of A.G. Russell Knives. The Blackout Crosslock knife is the latest version of a design that Buck Knives has been producing for over twenty years. The basic design, which Buck has long called the Model 183 Alpha Crosslock, features two blades, both with thumb studs to facilitate blade deployment and "spine locks" (my terminology) to secure the open blades. Three things distinguish the Blackout from its predecessor, the Alpha Crosslock PBS (now discontinued). The main blade of the Blackout has a modified tanto profile, the handle scales are G10 and the blades have a black oxide coating. The Crosslock PBS had a modified spear point main blade, anodized aluminum handle scales and uncoated blades. The secondary blade of the Blackout has a utility saw edge and a gut hook, like the secondary blade on the PBS. Specifications

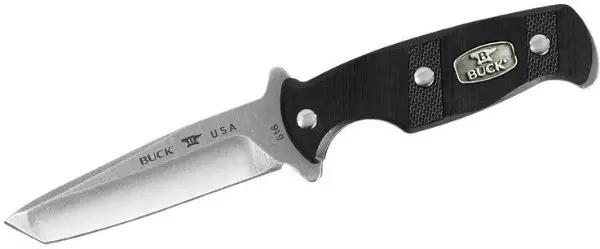

The good folks at Buck Knives provided a Blackout Crosslock for this review. I thank Stephaine Young and Rachel Rogers for making that happen. My out-of-the-box impression of the knife was that it is a clean, sensible design, with no cosmetic frills or gingerbread added (except for a pocket clip, which I will discuss later). I also noticed immediately that the knife feels solid and substantial. It weighed in at 4.55 ounces on my digital postal scale. Both blades are opened by use of thumb studs. Neither blade protrudes from the handle when the blades are closed, so the thumb studs must be used to initiate blade deployment. The good part of this is when one blade is open, the spine of the other blade is not interfering in any way with the grip on the knife handle. Not so good is the knife is very right-handed. When held in the right hand, either blade can be easily opened one handed, but I cannot come up with any way to open the blades with the left hand only, since the thumb studs are positioned for right hand use. The pivot pin of my review knife was screwed down tight, so that the blades resisted opening via normal pressure on the thumb studs. This was an easy fix with a T-10 Torx bit. I loosened the pivot pin cap screw about 1/16 of a turn and put a drop of fishing reel oil in the cracks between the pivot pin and blade tangs. Those two small tuning tweaks did the trick, so now the blades deploy easily and smoothly. The double locking blade design of the Crosslock is unique. A sturdy steel handle spine, which sits between the blades, has tensioned fingers milled on both edges. When either blade is opened, the finger tensioned to that side of the spine slips outward and jams behind a notch in the blade tang, locking the fully opened blade. It works like a liner or frame lock on a single blade knife, but the locking fingers deploy outward from the spine, not inward from a liner or handle frame. I think this is best described as a spine lock, rather than a liner or frame lock. Whatever one calls it, it is a neat way to lock both blades of the knife. The way in which the knife is built around the spine is straightforward. The blades rest between the spine and G10 handle scales. There are no liners between the scales and the blades and they are not needed. The pivot pin and cap screw hold everything together at the front of the handle, while the butt end of the handle has a pair of hard plastic spacers between the spine and the handle scales; these parts are held together with a pair of cross rivets. There is a lanyard hole through the butt of the handle. Buck calls the Blackout blade profile a modified tanto. Below is an image of another Buck knife, with a standard tanto blade; this may be compared with the image of the Blackout, above.  Buck Ops Boot Knife. Illustration courtesy of Buck Knives. A tanto blade has a straight or slightly curved cutting edge for almost all of its length and a short, straight leading edge that is steeply sloped to the blade tip. It is a speciality blade form designed primarily for piercing (stabbing) and secondarily for slashing. The otherwise awkward blade shape makes the tip strong and resistant to breakage if you hit bone on the way in. It lacks a curved belly on the cutting edge, so is a poor choice for slicing and other tasks that more conventional blades, such as clip and drop points, do well. The Blackout blade is profiled with a gently curved belly and just a hint of an angled corner on the cutting edge (a prominent tanto characteristic). This changes the geometry enough that the Blackout blade has a general purpose form. To me, it is closer to a drop point skinner than a tanto profile. Both the plain edge cutting blade and the saw blade have an honest three inches of sharpened edge. The factory edge of the main blade was extremely sharp ("shaving sharp," some would say) and the saw blade teeth are wickedly aggressive. The edge on the gut hook easily made test cuts through corrugated cardboard, heavy zip ties and thick canvas. The blades lock open with a reassuring clunk and have absolutely no play in any direction. Buck classifies the Blackout as a tactical style knife, but I see it as a multi-use outdoor and work utility tool. The main blade is long and robust enough to do a variety of medium duty cutting tasks. I can think of several uses for the hook, from field dressing and splitting the hide on a deer, to slitting the cladding on electrical wiring. The saw is there for small sawing tasks. The blade steel is 420HC stainless, with the main blade hollow ground. This blade steel and grind combination has been a mainstay on Buck knives for a long time. The handle size and the G10 scales are conducive to a secure grip when using the knife. The length and girth of the handle fits my medium-large hand well, while the textured and grooved surface of the scales make for a non-slip grip, dry or wet. My one small criticism of the handle is that it is slab sided, with squared edges. It could get uncomfortable to grip during long or heavy cutting sessions. Handle scales with more rounded edges and a bit more thickness at the middle on each side would have been more ergonomic. (See Knife Handle Ergonomics.) A utility knife frequently gets infested with dirt, grit and gunk of various sorts. Cleaning most folding knives can be a frustrating chore, but this knife is relatively easy to clean. The blade channels in the handle are open at the top and bottom. The knife can be cleaned by opening the blade and rinsing or swabbing out the channel. Repeat on the other side, if necessary. The Crosslock can be cleaned thoroughly without disassembly. If my Blackout gets really gunky, I would have no qualms about soaking it in a strong cleaning solution. The knife is made of stainless steel and G10, so it will not be damaged by anything short of strong acids or alkalis. Soak, rinse and dry it, then put a couple drops of lubricant in the pivot pin/tang area and it should be good to go. Speaking of maintenance, sharpening the main blade should be routine, since ease of sharpening is a virtue of 420HC. The hook can be touched up with a needle file. A dull saw blade would best be handled by sending the knife in for a factory sharpening. See the Buck Knives website for information on their knife sharpening and repair services, as well as the Buck Forever Warranty. The Blackout comes with a ballistic cloth belt pouch. It is of medium weight material and has belt loops on the back that allow for vertical or horizontal carry. The vertical carry loop will fit over belts up to about 1-3/4 inches wide, while the loops for horizontal carry will accommodate a belt up to 1-1/4 inches wide. The sheath is well made and adequate to its task. The knife also comes with a pocket clip, which can be mounted on either side of the tang end of the handle, for tip down carry. I am not a big fan of pocket clips, the majority of which I find to be poorly designed. The Blackout clip falls into that category. The spring steel clip is very stiff, which makes it a struggle to clip the knife into the corner of a jeans pocket or onto a belt. Further, the clip is positioned and shaped so that it tends to dig into the palm of my hand or finger tips (depending on which blade is deployed) when I am using the knife. I will likely do with this knife what I have done with all but a few knives I have that came with clips: remove the clip and carry the knife in the belt pouch, in a cargo pocket, or stowed in a small field pack. The clip is there, though, for anyone who prefers to use it. To summarize, my only mild criticisms of the Blackout knife are the handle ergonomics could be a bit better and I am not impressed with the pocket clip. These are things about which I am picky and they might not be significant for others. The Blackout Crosslock is a unique and intriguing knife. It offers three distinct functions in two blades, both of which lock securely when deployed. The size of the knife is right for medium duty tasks and it is one of the easiest folding knives to clean. The Blackout has a lot to recommend it for anyone looking for a capable and versatile, general purpose outdoors or tool kit knife. |