|

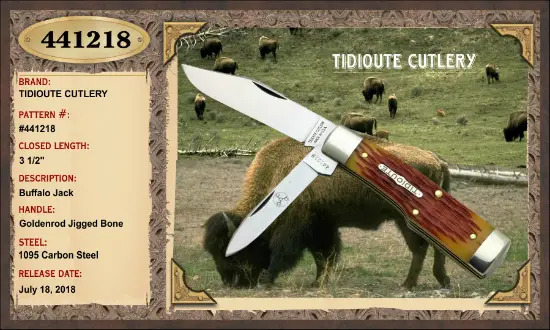

Great Eastern Cutlery 2017 Production Summary By Gary Zinn  GEC Tidioute #441218 knife. Image courtesy of Great Eastern Cutlery. Great Eastern Cutlery is a knife maker on the move. GEC is a newcomer to the traditional style pocket knife industry, having been in business since 2006. The company has gained a prominent position in its market segment in only a dozen years. I have followed the GEC saga with increasing interest, as it became apparent the firm was getting established in the market and as I began to get familiar with its products. I wrote a general article about the company over three years ago, followed two years ago by a summary of their 2014 and 2015 production records. I have also written reviews of four GEC knives I acquired during that period. (Links to these reviews are provided at the end of this article.) I wrote the production summary for 2014-2015 before GEC had released their 2016 production information and they have just posted production data for 2017. Comparing the data over these four years reveals that GEC is a growing enterprise. Production overview, 2014 through 2017 Here are basic production statistics for the years 2014 through 2017. (Total pieces produced each year rounded to the nearest 100 units.)

The GEC production records show that in 2007, its first full year of operation, the firm produced about 7300 knives from eight factory patterns. Production increased by a factor of 2.5 by 2014 and by a factor of 1.6 between 2014 and 2017. This is why I say the business is on the move. When I summarized the 2014 and 2015 data, I interpreted the similar production totals for those years as indicating that perhaps GEC had reached its limits of growth, either due to production capacity or market demand, or maybe both. However, the 2016 and 2017 production totals show this was not true. An interesting development over the four year period is that GEC doubled the number of factory patterns used in 2017, versus 2014; this made for a much wider range of knives offered to the market. Meanwhile, with the 60 percent increase in total pieces made over the period, average number of pieces per factory pattern did not decrease by much. The average was about 1200 pieces per pattern in 2014 and just under 1000 pieces per pattern in 2017. Factory patterns vs. knife models Here is a brief explanation of factory patterns and knife models, for those who may be light on the lingo. The term "factory pattern" refers to a particular knife frame, including length and shape. The maker may build multiple knife models from a given pattern, which differ from one another in the profile of the main blade, the number of blades and/or the handle material and treatment used. The knife pictured above is an example. The #441218 Buffalo Jack knife, hafted in Goldenrod Jigged Bone, is built on a 3.5" gunstock jack knife frame. This is GEC factory pattern 44, as noted by the first two digits of the knife model number. The next digit, 1, identifies the main blade as a regular clip point. The digit 2 indicates that this is a two blade knife and the number 18 indicates that this knife model was made in 2018. The model numbers of all GEC knives use this coding system, which is summarized on a tang number chart on the GEC website (www.greateasterncutlery.com). What is not embedded in the model number coding is the handle treatment. The production run, which includes the knife pictured is in progress as I write this (August, 2018), with the Goldenrod Jigged Bone handle being one of four handle treatments finished and shipped so far. This illustrates how 30 factory patterns morphed into 230 knife models in 2017. Regular production and special factory orders Decisions about which knife models to produce at a given time come about in two ways. First, GEC may make internal decisions on which factory pattern, blade specifications and handle treatments to use for a production run. I think of the knives produced on this basis as regular production items, which the firm then distributes among their dealers. The second method that leads to production runs are special factory orders (SFOs), generally initiated by one or another of the distributors who market GEC knives, or by an organization that orders a run of special knives for some purpose. (GEC calls these "club orders.") Presumably, the details of a SFO will be negotiated between the buyer and GEC, who will then produce an exclusive run of knives as per the contract specifications. SFOs are a significant part of total GEC production. The firm filled SFO orders totaling 9560 knives in 2017, for 22 distributors and clubs. This was not an unusual number, for there were some 9400 and 7750 SFO knives produced in 2015 and 2016, respectively. A variation on the SFO theme is that GEC has the production capacity to make knives for dealers who own unique tang stamps. For example, in 2017 GEC made nearly 2200 knives bearing the Northwoods tang stamp for Knives Ship Free. (The Northwoods brand is owned by Knives Ship Free.) Think of this as a double SFO, with GEC producing knives both to the dealer's specifications and with a non-GEC brand identity. GEC tang stamps I think it is interesting to note 2017 production within each of the four tang stamps (brand names) used by GEC. The numbers below are for regular production items, since these are tallied by tang stamp. Not all of the SFO knives are clearly identified as to tang stamp, which makes brand differentiated numbers for the SFO knives murky. Again, numbers are rounded to the nearest 100 pieces. Tidioute Cutlery = 9500 pieces; Northfield Un-X-LD = 7100 pieces; Great Eastern Cutlery = 900 pieces; Farm & Field Tool = 2700 pieces. (Total = 20,200 pieces) I explained the differences between the four brands in some depth in the general article Great Eastern Cutlery, so I will not repeat the detailed distinctions here. Suffice to say that Tidioute knives are the main product line, Northfield knives are premium products, Great Eastern Cutlery branded knives are designed to be no-frills everyday knives, while Farm & Field Tool models are robustly built to withstand hard use. Two aspects of 2017 production of knives with the Great Eastern Cutlery tang stamp bear noting. First, although the vast bulk of GEC knives are slip joint folders, Great Eastern Cutlery brand knives made in 2017 were all fixed blade hunting or fishing (fillet) knives. These were built on three traditional factory patterns: H23, H73 and F90. (H denotes a hunting knife pattern, F a fishing knife pattern.) Second, Great Eastern Cutlery branded knives generally have 440C stainless steel blades, while the other brands use 1095 carbon steel). However, the H23, H73 and F90 knives made in 2017 had 1095 blades. Miscellaneous products Although a relatively minor activity, GEC occasionally supplies knife parts to other firms and makes certain accessories in-house. In 2017 the firm supplied almost 1100 blade blanks for fixed blade hunting knives to Hess Knifeworks. They also made 268 leather sleeves, in large and small sizes, as an accessory for their folding knives. Although this is not explicit in the production data, I believe the leather sheaths for GEC fixed blade knives are made in-house; this would have been about 900 sheaths in 2017. GEC knife dealers The best place to start browsing for GEC knives is on their main website. Various interesting things may be accessed on or via the main page. For shoppers, the "Knife Releases" tab and "Releases by Year" sub-tab lead you to information on recent knife models that have been shipped to dealers. The image above was downloaded from the 2018 releases page, to give an idea of how the information is conveyed. The "Where to Buy" tab on the main page accesses a list of GEC knife dealers, which numbers thirty strong as I write this. If you are zeroed-in on a particular knife model you wish to buy, you may have to search several dealer sites to find what you want. Conclusion Anyone who appreciates traditional style pocket knives should be encouraged by the growth and development of Great Eastern Cutlery. This is especially true when we have seen the decline or demise of a number of firms that were, in earlier times, respected makers of traditional style knives, both folders and fixed blades. Schrade, Marbles, Camillus and Western are examples of U.S. firms that once made very good knives, but fell on hard times and went out of business, or had their brand names purchased by marketers of foreign made knives. As I write this, Queen Cutlery is closed, while attempting to reorganize and consolidate its debt. Time will tell whether Queen will be resurgent, or whether it will go the way of Schrade, et.al. Realistically, only Bear and Son Cutlery, Case and GEC, along with a small number of foreign firms (e.g., Boker) are still major forces in the slip joint folder and traditional style fixed blade knife markets. Based on my familiarity with the products of these participants in the market segment, I believe that Great Eastern Cutlery is, overall, making the best slip joint folder knives currently available. GEC is combining quality materials and immaculate workmanship to produce the best knives of their type that we have seen in a long time. Dollar for dollar, I think that GEC knives are as good as any of their type and better than many. Great Eastern knife reviews on Guns and Shooting Online |