|

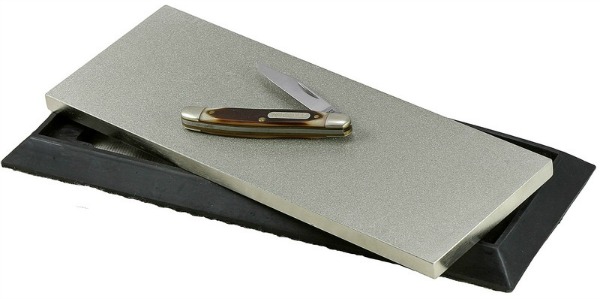

Sharpening S30V and Similar Super Steel Knife Blades By Gary Zinn  UltraSharp XLS Combination Diamond Sharpening Stone. Illustration courtesy of Best Sharpening Stones. There is a rumor going about that modern "super" knife blade steels, such as S30V, S35VN and such are hard to sharpen. I believe this is more internet myth than real world fact. I say this based on personal experience, research and logic. I concede that high performance knife steels may take more time and effort to sharpen than more pedestrian materials such as 1095, 420HC and the like. The home knife sharpener may have to modify or add to his/her tool set and learn some new techniques or nuances to get consistent, satisfactory results when sharpening more demanding steels. Although he has editorial standards, Guns and Shooting Online Owner/Managing Editor Chuck Hawks is not a control freak. He pretty much lets his editors and contributors follow their interests in writing topics, then works them onto the website as he sees fit. However, he occasionally makes a suggestion, as when he recently asked me for an article on sharpening S30V. I accepted the challenge, partly because it was in line with a project I had left on the back burner for some time, an article on "knives that are hard to sharpen." Ease of sharpening, edge retention and temper of selected steels Here is a list of selected blade steels, with scaled judgement values of their ease of sharpening (EoS) and edge retention (ER). The EoS and ER numbers are scaled 1 to 10, with EoS = 10 being easiest to sharpen and ER = 10 denoting highest edge retention. The Rockwell hardness index (Rc) range to which each steel is usually tempered for use in blades is also noted. The listed EoS and ER values are extracted from an article titled "Guide to the Best Knife Steel" by Matt Davidson. The article appears on the Knife Informer website. The index values suggested by Matt Davidson jibe closely with my own judgments of the ease of sharpening and edge retention of steels with which I have experience.

These are serviceable blade steels that have been popular for some time. I have a lot of experience with 420HC, 1095 and AUS-8, and I have always found them a snap to sharpen, with reasonable edge retention. Therefore, the EoS and ER index numbers for these steels seem reasonable to me. My experience with 14C28N and 440-C is that they sharpen a bit slower than the steels already mentioned. I judge that these two steels do show better edge retention than the other steels in the group. This first group of steels may be compared with the groups below.

I currently have two knives each with S30V and ATS-34 blades; all have been acquired within the last three years. My experience is that they show markedly better edge retention than do the steels in the first group. It certainly takes somewhat more effort to sharpen S30V and ATS-34 than is normal with 420HC through 440-C, but I would not categorize them as hard to sharpen. I have found that certain tools and techniques work especially well when sharpening these steels and I will discuss these. I italicized three of the steels in this group to denote that I have not worked with them. I used CTS-XHP and 154CM to bound the group, while S35VN is a refined version of S30V. The data sheet for S35VN includes the assertion that it is easier to machine than is S30V.

I have no experience with Elmax steel, but I have four pocket knives with D2 blades. The EoS score that Matt Davidson gave D2 surprises me a bit. I have never been stymied when sharpening D2; to me it behave much like S30V and ATS-34. Maybe I just do not understand that D2 is supposed to be difficult to sharpen. (My opinion on how D2 sharpens is supported by the Crucible data sheet for S30V, wherein it is stated that the grind-ability of S30V, "is comparable to that of D2.") I threw in S110V to define the top of the range in blade sharpening difficulty and tenacious edge retention. Here is how Matt Davidson describes S110V: "Quite simply the ultimate in wear resistance and edge retention on 'mainstream' knife production. Still relatively rare in the marketplace and arguably indistinguishable from CPM-S90V outside of the laboratory, but the fact remains that nothing holds an edge like Crucible's CPM-S110V. It is costly, a bitch for knife makers to work with and sharpening can drive you nuts, but a CPM-S110V blade will hold up for a ridiculous amount of time." I would decline the challenge of hand sharpening S110V or its ilk. (One person who wrote about his attempt to sharpen S110V wondered, "Is this stuff even steel?") I would recommend buying a knife this intractable only from a maker that offers factory sharpening services and letting them deal with it when sharpening is eventually required. Note that the steels in the first group are normally tempered to no higher than Rc 59 or 60 for making blades, while those in the second and third groups may be tempered to Rc 61 or 62. I believe that tempering has an often overlooked effect on ease of sharpening. Experience has convinced me that blades tempered in the Rc range of 57 - 60 give the best balance between ease of sharpening and edge retention. (This pertains to knives used for normal cutting tasks; impact cutting tools such as cleavers, machetes and such should be tempered to lower Rc values.) I am also convinced that Rc 60 is a tipping point, in the sense that a blade tempered anywhere above Rc 60 is generally noticeably harder to sharpen than one of the same steel tempered to Rc 60 or a bit less. Unfortunately, many knife makers do not specify the Rc values to which they temper their blades. However, I want to know the Rc of a particular knife model whenever I can get that information, for it helps me anticipate how the knife will perform in use and respond to sharpening. Manual knife sharpening I learned to sharpen my first pocket knife before I was seven years old. (Thanks, Dad!) That was over sixty years ago and I have sharpened many thousands of knives since. My long time go-to technique is freehand manual sharpening, using bench stones or "tri-hone" stone sets for bevel grinding, crock sticks for finishing edge bevels and either a butchers steel or leather strop for final honing. Common knife steels, such as those in the first group listed above (420HC through 440-C) can be easily sharpened freehand, or by using guided manual sharpeners, using these stones, finishing and honing tools. However, the modern super steels challenge the capabilities of traditional sharpening stones. The silicon carbide and Arkansas stones on my tri-hone will grind ATS-34, D2, and S30V blades, but only very slowly. There are materials that are much more efficient for grinding bevels on modern steels, such as those in the second group above, plus D2 and Elmax. Tools for sharpening popular super steels I recommend diamond or ceramic sharpening stones for working the modern steels that are resistant to traditional sharpening stones. Diamond and alumina ceramic sharpeners are so much harder than any steel that they will generally cut tough steels almost as readily as more conventional stones do the common steels. The major play here is in diamond sharpeners. Leading brands such as DMT, EZE-LAP and UltraSharp offer a wide range of diamond sharpening stones for freehand bench sharpening. The selection of alumina ceramic bench stones is much more limited, with Spyderco offering the best selection. I believe that, currently, the best value in a diamond bench sharpener is the Work Sharp Guided Sharpening System. This highly affordable tool includes two interchangeable diamond sharpening plates, with different grits, and a ceramic rod honing module. Adding the upgrade kit gets you two additional diamond plates, with two additional grits and a leather faced stropping plate. For those who like manual guided sharpening systems, the leading brands of highly affordable guided sharpeners (DMT, GATCO, Lansky) all offer sets with diamond sharpening stones. If one favors the tri-hone type of bench sharpener, there are some of these with diamond or ceramic stones, too. The Lanky Diamond, Alumina Oxide, and Ceramic Tri-Hone and Smith's Diamond Tri-Hone are examples. An alumina ceramic crock stick type sharpener is, to me, a must-have for setting and smoothing final edge bevels. There are several makes and models available, but I favor the Lansky Masters Edge tool. I like this one because it includes both medium and fine grit round sharpening rods, a triangular rod and the option of 17, 20, or 25 degree mounting angles for the round rods. Speaking of sharpening rod systems, anyone who wishes to put together a kit for sharpening super steel blades might want to consider the Spyderco Tri-Angle Sharpmaker. The standard kit includes medium and fine grit triangular ceramic rods that can be mounted at either 15 or 20 degree angles. Adding a pair of diamond or cubic boron rods yields everything needed to do all but the heaviest grinding on super steel blades. For a final honing touch, one can use either a butchers steel or a strop. Either works well on both common and super steels. I do NOT recommend either manual or powered (consumer grade) pull-through knife sharpeners for any knife blade. In my experience, these have severe limitations and disadvantages, culminating in the fact that they are more likely to damage blade bevels than they are to get good sharpening results. I have found this true for use on common steels, so I cannot imagine they will work well on super steels. My non-endorsement of powered sharpening tools emphatically includes using high speed power tools, such as bench grinders and belt sanders. Power tools such as these are not designed for sharpening knives and are likely to damage the knife or injure the operator. You have been warned. Finally, I will not discuss professional grade power tools designed for sharpening knives and other edged tools, because they are cost efficient only for someone who sharpens lots of knives and gets paid for doing so. The occasional sharpener is better off buying suitable manual sharpening tools and using the rest of the $1000 or so that a professional tool would cost to buy some nice knives. See Knife Sharpness, Sharpening Methods and Tools for a fuller discussion of sharpening methods and tools. Sharpening super steels - some key points One writer has said that "success with sharpening is probably about 80% technique and only 20% tools." I agree with the essence of the statement and will not quibble over the exact relative percentages. Put another way, once suitable tools have been selected the real results come from the techniques used to do the sharpening. I wrote extensive articles on freehand sharpening and honing techniques a couple of years ago (Knife Sharpening 101 - The EZ Method and Knife Honing with Crock Sticks and a Butchers Steel). I will not go into step-by-step techniques here, but I do want to stress a few key points that I feel are especially important when one sharpens super steel blades. First, we need to define degrees of knife sharpness and review types of blade grinds. Sharpness defined I have a qualitative ranking system for describing the sharpness of knives:

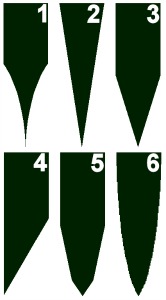

Here is a simple method I use to evaluate the sharpness of a knife and what I mean by these degrees of sharpness. To test sharpness, I use a magazine or catalog with pages of thin coated paper. I pick up a page or two, punch the tip of the blade through the paper just below where I am holding it by the outside edge, and slice downward through the page(s). If the paper does not cut cleanly, then the knife is Not Sharp. If the cut is clean, but with noticeable resistance, then the blade is Sharp Enough. A clean, easy cut with little resistance indicates a Very Sharp blade and if the knife zips through the paper with virtually no resistance it is Extremely Sharp. This is a quick and consistent method of evaluating blade sharpness. NS means that some sharpening work is needed before the knife can be efficiently and safely used. SE means that the edge is acceptable for doing normal cutting tasks. When I sharpen a knife, I generally aim to get it to VS condition; then it will easily cut almost anything that should be cut with a knife and I will likely be able to use it for quite awhile before a touchup is needed. Extremely Sharp is my term for a knife that generally would be called razor sharp, or shaving sharp. I do not use these terms, because we are talking about knives, not razors. I do not sharpen knives to ES condition often, mainly because it is extra work to get an edge to this keenness and it will usually dull back to VS condition very quickly. I will sometimes hone a special purpose blade, such as a Wharncliffe, to ES if I need to use it for fine work (e.g., cutting stencils or such). In my opinion a knife should generally be sharpened to VS condition. Whenever the edge falls back to SE condition, it should be touched up at the first opportunity. This makes for a much easier sharpening job than if one lets a knife dull to NS condition before resharpening. Blade grinds (primary bevels) Successful sharpening starts with knowing how a given blade is ground. Here are illustrations of the most common blade grinds or bevels: #1, hollow; #2, flat; #3, sabre (or scandi); #4, chisel; #5, double (a.k.a. compound); #6, convex.  Blade grinds. Illustration courtesy of Wikipedia. Hollow and flat ground blades are beveled to a rough edge, then a narrow micro bevel is used to form the final cutting edge. Sabre (also called scandi) blades usually have a micro bevel edge, but sometimes are ground with a straight primary bevel only. Double bevel blades always have both primary and micro bevels, with the primary bevel being somewhat narrower that that found on hollow or sabre ground blades. The chisel grind, which never has a micro bevel on the cutting edge, is seldom seen on common pocket, hunting, or outdoors knives. It is mostly used on certain chef knives, some heavy duty "tactical" knives and a few novelty knives, such as the half-handled CRKT K.I.S.S. and P.E.C.K. knives. The convex grind is a curved bevel, formed by each side of the blade being ground in a shallow arc to the cutting edge. The convex grind is seldom seen on factory edges, but some custom knife makers and expert sharpeners use it. It is the most difficult of the six basic grinds to execute well. Micro bevels I have used the term "micro bevel" repeatedly, so I need to make clear what I am talking about. The primary (edge) bevel serves to grind the blade from its full thickness to a rough edge. The micro bevel then applied to form the final cutting edge. An explanation from Knife Informer states, "The micro bevel is created when the (sharpening) angle is raised on the knife in relation to the sharpening stone." Micro bevels are both efficient (in terms of sharpening effort) and effective (in terms of getting a sharp and durable cutting edge) on all blade steels, common or super. I will use the Morakniv Companion knife to illustrate what I mean. I have one of these inexpensive fixed blade knives, with a scandi ground common stainless steel blade. As sharpened at the factory, the primary bevel formed the cutting edge, with a bevel angle of about 11 degrees on each side of the blade. (Trust me, I did the math.) The first time I needed to sharpen my Companion, I cut a 17 degree micro bevel on each side. I added the micro bevel to (1) make the cutting edge more durable and (2) make routine sharpening quicker and easier. Concerning edge durability, the larger the angle of the cutting edge bevel, the more durable it will be in use. Other things equal, an edge bevel of 17 degrees each side will cut considerably longer before sharpening is needed than will one of 11 degrees each side. Sharpening a micro bevel is quicker and easier than sharpening a wider primary bevel, because much less steel needs to be ground away to restore the edge on a micro bevel. The primary bevel of the Mora Companion is about 5mm wide, while the micro bevel I added is barely 1mm wide. Tips for sharpening super steels Bearing in mind the points I have made regarding degrees of sharpness, blade grinds and micro bevels, I can now share some simple tips that are especially important when sharpening super steels. Tip #1 - sharpen only the micro bevel: Some people seem to believe that the first step in a routine blade sharpening is to work on the primary bevel. Not so. An edge that is simply duller than desired (as opposed to being seriously damaged in some way) can easily be sharpened by working the micro bevel only. A relevant example is a Gerber Gator Premium Clip Point Folding Knife that I acquired recently. The S30V blade of this knife is sabre ground, with a primary bevel about 15mm wide and a 1mm wide micro bevel. This blade is set up for hassle free sharpening, out of the box. All I had to do when it needed a first touchup sharpening was to get a feel for the angle of the micro bevel (about 15 degrees, as best I can judge) and then sharpen it at that angle. I will not have to worry about grinding that wide primary bevel for a long time, if ever. This is good, for I would not want to grind down such a wide bevel by hand, especially on a super steel. Regrinding wide primary bevels is a major job on any steel and would be onerous on super steels. Anyone who has a super steel knife that needs work on the primary bevel would be better off sending it in for factory resharpening, rather than trying to do it at home. Tip #2 - establish and maintain appropriate bevel angles: To reiterate a point made earlier, the larger the angle of the cutting edge bevel, the stronger and more durable the edge will be. There are practical boundaries, though, which I will state outright: a micro bevel angle between about 15 degrees each side and about 20 degrees each side is a practical range for most general use pocket, hunting and outdoors knives. Micro bevels in this range gives a good balance between cutting performance and edge durability for most knives and uses. I have the micro bevel angle on most of my knives set at about 17 degrees each side, with some (mostly thin) blades set up with 15 degree micro bevels and a few thick blades set at 20 degree angles. This works for me. The notable exceptions to the 15 - 20 degree cutting edge bevel rule are fillet knives and heavy duty knives and machetes. Fillet knives work best with a single shallow bevel, say 12 to 15 degrees each side. With heavy duty knives and machetes, the party is just getting started at 20 degrees; 25 degree cutting edge bevels on each side are generally good for these blades. Double or convex bevels work best for brute knives. Tip #3 - sharpen early: This tip is a reemphasis of another statement I made earlier: generally, a knife should be sharpened to VS (Very Sharp) condition. Then, whenever the edge falls back to Sharp Enough condition, it should be touched-up at the first opportunity. I did just this with my Gerber Gator Premium knife. Its first touch-up sharpening was done on my crock stick sharpener, using both the medium and fine rods. I gave the blade a dozen strokes on each side, on each set of rods. That is all it took to restore the edge to VS (ES borderline) sharpness. This was a much easier sharpening job than if I had let the knife dull to NS condition before resharpening. Tip #4 - do not over sharpen: Much of the buzz I read on internet forums about sharpening focuses on getting blades "razor sharp," or some such nonsense. The idea that a pocket, hunting, or outdoors knife should or must be sharpened to the acuity of a surgical scalpel is silly. A blade that meets the test to be called Very Sharp (VS) is keen enough to efficiently cut anything that you or I generally need to cut. Trying to sharpen knives beyond VS condition is usually an inefficient use of time and effort. Tip #5 - do not make the sharpening job any harder than necessary: In addition, know when to seek professional help. Here are a few basic scenarios to illustrate this tip. All assume that only the micro bevel will be worked. First, suppose your knife is VS, but feels just a bit off by the time you have finished some routine cutting task. It may be that all that is needed are a few passes across a butchers steel or strop to restore the edge to that "just right" condition. Simple and quick. Next, suppose you have just done an extended cutting session and feel that your knife is beginning to dull, just a bit (it has faded from VS to SE condition). The blade likely needs what I think of as a touchup sharpening. Usually, this can be done on a ceramic rod tool, starting with as many strokes across medium grit rods as seem needed, followed by a similar number of strokes on fine grit rods. If this restores the edge, finish with a butchers steel or strop, and call it good. You have let your knife get dull enough that it is barely SE. It is time to break out your sharpening stone tools and begin working the micro bevel with the soft Arkansas stone (for common steel blades), or medium grit diamond stone (for super steels). Next, use a hard Arkansas stone on common steel, a fine grit diamond stone on super steel. When the edge has been improved to high SE or low VS condition, finish with ceramic rods and butchers steel or strop. Darn! You got careless and let your knife get really dull (NS condition). Do penance by starting sharpening with a course silicon carbide stone (for common steels) or a course grit diamond stone (for super steels). Then, follow the sequence described in the preceding paragraph to get the rest of the way to a VS blade. Oh Crap! Somehow, you have really messed up the edge of your blade. (Nicks or chips, perhaps a distorted edge or damaged tip.) Start by carefully examining and objectively assessing the damage. If you think it can be fixed by working the micro bevel only, start with an extended grinding session on your course silicon carbide or course grit diamond tools (as appropriate for the steel). If heavy grinding removes the damage and gets you back to an even rough edge, be thankful and proceed to sharpen your now NS blade back to where you want it. If a blade is damaged enough to require heavy grinding of the primary bevel, the better part of valor is to consult with the knife maker or a reputable blade smith (if you know one) about repair service. Sorry, but this blade needs professional care. Tip #6 - do not attempt to regrind the primary bevel: I know I said this the other way around in Tip #1, but it bears repeating from a "do not" perspective. The stories about so-called super steels being hard to sharpen mostly have a common circumstance or theme: the person doing the sharpening was trying to regrind the primary bevel on the blade. This is mostly futile with super steel blades and is problematical with common steels. Referring back to the earlier summary of blade grinds, consider flat and hollow ground blades. The entire sides of flat ground blades are the primary bevels, while hollow ground blades have concave primary bevels. Regrinding a flat ground blade is an onerous task to do by hand on any steel (common or super) tempered to normal cutting blade Rc values. It is almost impossible for the home sharpener to regrind the primary bevel of hollow ground blades, due to its concave shape. If one has a flat or hollow ground knife, whatever the blade steel, that needs the primary bevel reworked, the knife should be either returned to the maker for factory sharpening, or put in the hands of a professional sharpener who can be trusted to do the job right. I have been known to regrind the primary bevels on double or scandi ground common steel blades. It is not that big a deal, but does take time. However, I do not plan to ever work the primary bevels on any double or scandi super steel knives. This would be not only frustratingly hard work to do manually, but will likely never be necessary. My experience with ATS-34, D2, and S30V blades is that they need to be resharpened infrequently and that little steel is removed in sharpening the micro bevels of these blades. I cannot foresee a time when I may have removed enough steel from the edge that the primary bevels of these blades might need to be reground. If that time comes, I will seek professional help. Chisel ground blades must be sharpened by working the entire bevel. This is not an especially daunting task with common steels, but could be a bear to do on super steels. My advise is to not buy a super steel knife with a chisel ground blade (if such beasts are even on the market). I have already mentioned that convex ground blades are tricky to sharpen. Doing so requires unique tools and techniques, plus skill and practice, whatever the steel. (An article on convex bevel sharpening is forthcoming.) Conclusion The do-it-yourself knife sharpener need not be intimidated by the popular super steels, such as S30V, S35VN, ATS-34 and D2. They are steel, after all, and all but the most extreme of them can be manually sharpened with the right grinding and honing tools, appropriate sharpening techniques and somewhat more patience than might be required to sharpen more common steels. |